wifiwireles

Just Hatched

Frequency conversion technology adjusts the operating speed of motors, compressors and other electrical equipment by changing the frequency of electrical signals. In practical application, frequency converter is the core device of frequency conversion technology, and pulse width modulation (PWM) technology and sine wave pulse width modulation (SPWM) technology are important means to realize frequency converter control.

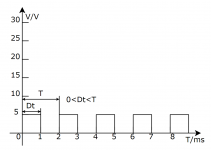

First, let's take a look at the PWM modulation technique. The PWM modulation technology realizes the adjustment of the output voltage by controlling the width of the pulse signal. In frequency conversion technology, PWM is widely used in frequency converters to control the speed and torque output of motors. By changing the duty cycle (ratio of pulse width to period) of the pulse signal, precise control of the motor can be achieved. When the output voltage needs to be increased, the width of the pulse signal is increased; when the output voltage needs to be reduced, the width of the pulse signal is decreased. In this way, the motor can maintain stable speed and torque output under different load conditions. At the same time, PWM modulation technology also has the advantages of fast response, high control precision, and high efficiency, and is widely used in various power control systems. The PWM modulation waveform is shown in Figure 1:

Efficiency: Since PWM technology can control the output voltage and frequency of the motor by adjusting the pulse width, it can realize the high-efficiency operation of the motor under different load conditions. By reducing the rated voltage of the motor, PWM technology can reduce the power consumption of the motor and improve the overall efficiency.

Precise control: PWM technology has the characteristics of fast response and high control precision. By fine-tuning the pulse width and period, the precise adjustment of the motor speed and torque can be realized to meet the needs of different applications.

Reduce mechanical impact: PWM technology can realize soft start and soft stop of the motor, which reduces the impact and wear of the mechanical system and prolongs the service life of the equipment.

Although PWM technology has many advantages, there are some limitations:

Harmonic issues: PWM technology will introduce harmonic components when generating pulse signals, which may cause interference to power networks and other equipment. In order to reduce harmonics, filtering and suppression measures need to be taken, which increases the complexity and cost of the system.

Switching loss: PWM technology uses high-frequency switching devices, and the frequent operation of the switch will cause switching loss. These losses are converted to heat energy, requiring a proper cooling system to cool the circuit.

EMI Interference: Due to high-frequency switching operations, PWM technology may generate electromagnetic interference (EMI), causing interference to surrounding electronic devices and wireless communication systems.

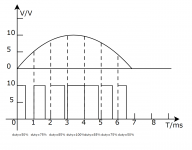

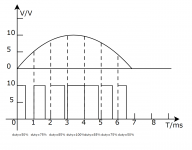

Another common modulation technique is SPWM modulation technique. The SPWM modulation technology realizes the modulation of the voltage by generating a triangle wave and a reference sine wave similar to the required output sine wave. In frequency converters, SPWM modulation technology is widely used to generate power supply voltage to control the speed and output power of the motor. It determines the width of the pulse signal at each moment by comparing the phase difference between the triangle wave and the reference sine wave. By adjusting the size of the phase difference, the precise regulation of the output voltage can be realized. SPWM modulation technology has the advantages of good output waveform quality and low harmonic content, and is widely used in high-precision power control systems. The sine wave half-wave waveform of SPWM modulation is shown in Figure 2:

High output waveform quality: SPWM technology can generate output waveforms similar to sine waves, with lower harmonic content and better waveform quality. This helps reduce harmonic losses in motors and other equipment, improving system efficiency and stability.

High control precision: SPWM technology can realize precise control of motor output signal. By adjusting the phase difference between the reference sine wave and the triangular wave, the width of each pulse can be fine-tuned, thereby realizing precise adjustment of the motor speed and torque.

Low noise: Since the SPWM technology can generate a smooth output waveform, the motor generates low noise during operation. This is very important for applications with high noise requirements, such as audio equipment and precision instruments.

Although SPWM technology has many advantages, there are some limitations:

High system complexity: SPWM technology needs to generate reference sine waves and triangle waves, and perform phase difference comparison and pulse width adjustment. This requires complex circuits and algorithms, increasing system complexity and cost.

Harmonic issues: Although SPWM technology can reduce harmonic content, low frequency harmonics may still exist. This requires filtering and other compensation measures to reduce the effects of harmonics.

High requirements on switching devices: SPWM technology uses switching devices to achieve pulse width regulation, which requires switching devices to have fast switching speed and low switching loss.

The application of PWM modulation technology and SPWM modulation technology in frequency conversion technology enables us to realize the precise control of the motor and improve the efficiency and reliability of the system. The application of these technologies not only plays an important role in daily life such as home air conditioners, elevators, and water pumps, but also promotes the improvement of production efficiency in the industrial field. For example, in industrial production, through the application of PWM modulation technology and SPWM modulation technology, the soft start and soft stop of the motor can be realized, the mechanical shock can be reduced, and the service life of the equipment can be extended. At the same time, precise motor control can also improve the accuracy and stability of the process and improve the quality of the product.

Ebyte is committed to helping the development of IoT, intelligence and automation more powerfully every day, improving resource utilization, more products and more information, and interested partners can log on to our official website: to learn more, and we are ready to answer questions online!

First, let's take a look at the PWM modulation technique. The PWM modulation technology realizes the adjustment of the output voltage by controlling the width of the pulse signal. In frequency conversion technology, PWM is widely used in frequency converters to control the speed and torque output of motors. By changing the duty cycle (ratio of pulse width to period) of the pulse signal, precise control of the motor can be achieved. When the output voltage needs to be increased, the width of the pulse signal is increased; when the output voltage needs to be reduced, the width of the pulse signal is decreased. In this way, the motor can maintain stable speed and torque output under different load conditions. At the same time, PWM modulation technology also has the advantages of fast response, high control precision, and high efficiency, and is widely used in various power control systems. The PWM modulation waveform is shown in Figure 1:

Figure 1 PWM modulation waveform

PWM technology has the following advantages:Efficiency: Since PWM technology can control the output voltage and frequency of the motor by adjusting the pulse width, it can realize the high-efficiency operation of the motor under different load conditions. By reducing the rated voltage of the motor, PWM technology can reduce the power consumption of the motor and improve the overall efficiency.

Precise control: PWM technology has the characteristics of fast response and high control precision. By fine-tuning the pulse width and period, the precise adjustment of the motor speed and torque can be realized to meet the needs of different applications.

Reduce mechanical impact: PWM technology can realize soft start and soft stop of the motor, which reduces the impact and wear of the mechanical system and prolongs the service life of the equipment.

Although PWM technology has many advantages, there are some limitations:

Harmonic issues: PWM technology will introduce harmonic components when generating pulse signals, which may cause interference to power networks and other equipment. In order to reduce harmonics, filtering and suppression measures need to be taken, which increases the complexity and cost of the system.

Switching loss: PWM technology uses high-frequency switching devices, and the frequent operation of the switch will cause switching loss. These losses are converted to heat energy, requiring a proper cooling system to cool the circuit.

EMI Interference: Due to high-frequency switching operations, PWM technology may generate electromagnetic interference (EMI), causing interference to surrounding electronic devices and wireless communication systems.

Another common modulation technique is SPWM modulation technique. The SPWM modulation technology realizes the modulation of the voltage by generating a triangle wave and a reference sine wave similar to the required output sine wave. In frequency converters, SPWM modulation technology is widely used to generate power supply voltage to control the speed and output power of the motor. It determines the width of the pulse signal at each moment by comparing the phase difference between the triangle wave and the reference sine wave. By adjusting the size of the phase difference, the precise regulation of the output voltage can be realized. SPWM modulation technology has the advantages of good output waveform quality and low harmonic content, and is widely used in high-precision power control systems. The sine wave half-wave waveform of SPWM modulation is shown in Figure 2:

Figure 2 SPWM modulated sine wave half wave

SPWM technology has the following advantages:High output waveform quality: SPWM technology can generate output waveforms similar to sine waves, with lower harmonic content and better waveform quality. This helps reduce harmonic losses in motors and other equipment, improving system efficiency and stability.

High control precision: SPWM technology can realize precise control of motor output signal. By adjusting the phase difference between the reference sine wave and the triangular wave, the width of each pulse can be fine-tuned, thereby realizing precise adjustment of the motor speed and torque.

Low noise: Since the SPWM technology can generate a smooth output waveform, the motor generates low noise during operation. This is very important for applications with high noise requirements, such as audio equipment and precision instruments.

Although SPWM technology has many advantages, there are some limitations:

High system complexity: SPWM technology needs to generate reference sine waves and triangle waves, and perform phase difference comparison and pulse width adjustment. This requires complex circuits and algorithms, increasing system complexity and cost.

Harmonic issues: Although SPWM technology can reduce harmonic content, low frequency harmonics may still exist. This requires filtering and other compensation measures to reduce the effects of harmonics.

High requirements on switching devices: SPWM technology uses switching devices to achieve pulse width regulation, which requires switching devices to have fast switching speed and low switching loss.

The application of PWM modulation technology and SPWM modulation technology in frequency conversion technology enables us to realize the precise control of the motor and improve the efficiency and reliability of the system. The application of these technologies not only plays an important role in daily life such as home air conditioners, elevators, and water pumps, but also promotes the improvement of production efficiency in the industrial field. For example, in industrial production, through the application of PWM modulation technology and SPWM modulation technology, the soft start and soft stop of the motor can be realized, the mechanical shock can be reduced, and the service life of the equipment can be extended. At the same time, precise motor control can also improve the accuracy and stability of the process and improve the quality of the product.

Ebyte is committed to helping the development of IoT, intelligence and automation more powerfully every day, improving resource utilization, more products and more information, and interested partners can log on to our official website: to learn more, and we are ready to answer questions online!